General Information

Cable Trays General Information

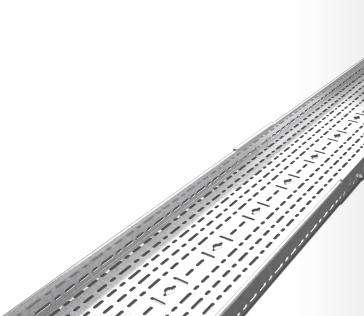

EAE cable trays and ladders provide high-strength cable protection that protects the cables from external factors. EAE cable trays are mass produced with the 'Roll Forming' method on automatic production lines. The standard tray length is 3m. 6m can be produced upon request.

Cable tray supports and protects power cables, communication cables and wires, and helps to expand, make stable and restructure the cable network.

Products

Types of Cable Tray

EAE cable tray types are mass produced with the "Roll Forming" method and product types that will meet all your needs. Cable tray selection is made in compliance with the number, diameter, weight of the cables that will pass through the duct and the environment it is to be utilized in.

Types of Cable Tray

Types of Cable Tray According to Coating Type

Galvanized Cable Tray

If a sheet metal cable tray is coated with Zinc (Zn), it is called a galvanized cable tray. Due to the nature of the metal used in sheet materials, it tends to interact with oxygen. As a result of this action, a copper-colored brownish surface damage begins to occur on the surface of the material, which we call corrosion.

Over time, this corrosion deforms the structure of the sheet material and causes it to scatter easily. To prevent this corrosion, its surface must be covered with a material that will prevent its contact with oxygen. Zinc (Zn) is the most preferred coating material in the industry due to its economic specifications. The process of coating with zinc is called galvanizing.

- There are three different methods according to galvanization method and coating thickness:

- Pre-galvanized Coating

- Hot-Dip Coating

- Electro Galvanized Coating

Types of Cable Tray

Types of Cable Tray According to Material Type

Electro-galvanized coating is a shiny looking chemical material that gives hardness to the galvanized material, albeit partially, by sticking the melt removed from the zinc anode with chemical alloys to the material on the cathode. The coating thickness is 8-12 µ.

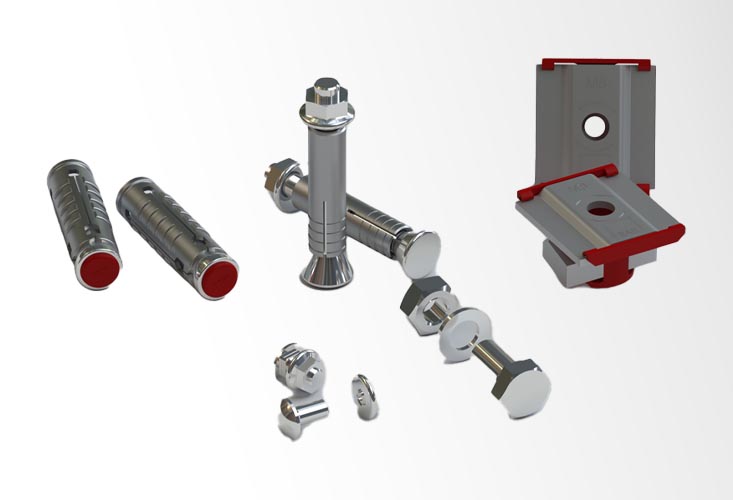

At the same time, the coating thickness can be controlled on demand. By increasing the electric charge or slowing its velocity across the coated steel surface, the coating thickness can be increased. Electro-galvanized is a thin coating and provides strong protection. This method is generally used in wire cable trays and accessory parts such as dowels, rods, nuts, and bolts. TS 149 Standard is used for Electro-Galvanized coating.

Types of Cable Tray

Cable Tray Types According to Design Type

It is the name given due to the shape formed, because of forming the edge parts during the production of cable trays. Since the thickness of the cable tray is thin, the edges are extremely suitable for cutting cables. To prevent this, it is very important to use a curved form.